Tray Layer

-

The Tray Layer (also called Tray Stacker or Tray Loading Robot) is an automated solution for efficiently loading product trays onto multi-tier material racks or carts before pre-freezing and freeze-drying. It ensures precision stacking, labor reduction, and improved hygiene compliance in high-capacity food processing environments.

-

High-Speed Loading:

Handles up to 8–12 trays per minute.

Multi-Axis Robotic Arm or Gantry System:

Precise movement with ±2 mm accuracy.

Customizable Rack Configurations:

Supports single-side or four-side loading for large racks.

Cold Room Compatible:

Designed to operate in sub-zero environments (-20°C or below).

Sanitary Design:

Constructed from AISI 304/316 stainless steel, suitable for food processing.

Safety & Compliance:

Meets FDA, EHEDG, and ISO 22000 standards.

-

Model:PPJ01-00+LD01-00

Size(mm):3150×1150×2300

The hopper has an eccentric vibration to prevent material clamping

Weight(kg):750

Belt Speed:60mm/s

Hopper Volume:0.3m³

Capacity:3500 kg/h

Air Pressure:6 bar

Power Supply:480V/60Hz/2*1.26KW+0.75KWLoad Capacity: Up to 25 kg per tray.

Rack Size: Configurable (e.g., 64 trays per rack, 16 per side).

Automation Integration: Compatible with PLC/SCADA systems for full line control.

Power Supply: 380V / 50Hz, optional energy-saving mode.

Tray Loading Machine

-

The Tray Loading Machine is a fully automated system designed to load product onto trays with precision, speed, and hygiene. It is an essential component in freeze-drying operations and high-capacity food production facilities, reducing manual handling and improving overall efficiency.

-

High-Speed Loading

Capable of handling multiple trays per minute.

Optimized for continuous production with minimal downtime.

Precision & Consistency

Accurate product placement to maintain uniform thickness for freeze-drying.

Adjustable fill patterns for various product shapes and sizes.

Flexible Integration

Interfaces with conveyors, AGVs (Automated Guided Vehicles), and robots.

Configurable for single or multi-line systems.

Hygienic Design

Stainless steel construction (SS304/SS316L) for food safety.

Easy-clean design with CIP (Clean-in-Place) or quick disassembly.

Smart Controls

HMI/PLC interface for easy recipe changes and system diagnostics.

IoT connectivity for real-time performance monitoring.

-

Model:ZPJ01-01

Size(mm):8750×2580×2850

All are driven by servo motors and with a laying guide mechanism, electronic scale

Weight(kg):2750

Tray Size(mm):671*604*37

Tray load Weight:Max.8.5 kg

Capacity:400 trays/h

Air Pressure:6 bar

Power Supply:480V/60Hz/50A

Capacity: Up to 10–30 trays per minute, depending on product and tray size.

Tray Sizes: Customizable (common range: 400×600 mm, 600×800 mm).

Accuracy: ±2% on fill weight per tray.

Tray Unloader Machine

-

The Tray Unloading Machine is a fully automated solution designed to remove trays of finished product from freeze-dryers or processing lines with precision and efficiency. It ensures minimal manual handling, protecting product quality while maximizing throughput.

-

Automated High-Speed Unloading

Handles multiple trays per cycle for continuous operation.

Reduces cycle time compared to manual handling.

Gentle Product Handling

Specialized gripping or vacuum systems to avoid product damage.

Stable transfer for fragile or lightweight freeze-dried products.

Flexible Integration

Connects with conveyor systems, AGVs, or robotic arms.

Compatible with single or multi-freeze-dryer configurations.

Hygienic Design

Stainless steel build (SS304 or SS316L).

Smooth surfaces for easy cleaning and compliance with FDA, BRCGS, EHEDG standards.

Intelligent Controls

PLC + HMI interface with recipe-driven automation.

Integration with SCADA/MES for real-time monitoring and reporting. Performance Metrics

-

Model:XPJ01-01

Size(mm):5300×3900×2850

All are driven by servo motors and with an automatic feeding mechanism.

Weight(kg):2500

Tray Size(mm):671*604*37

Tray load Weight:Max.8.5 kg

Capacity:400 trays/h

Air Pressure:6 bar

Power Supply:480V/60Hz/50A

Capacity: 10–30 trays per minute (depending on system layout).

Tray Size: Customizable (typical range 400×600 mm or 600×800 mm).

Safety: Full guarding and emergency stop features for operator protection.

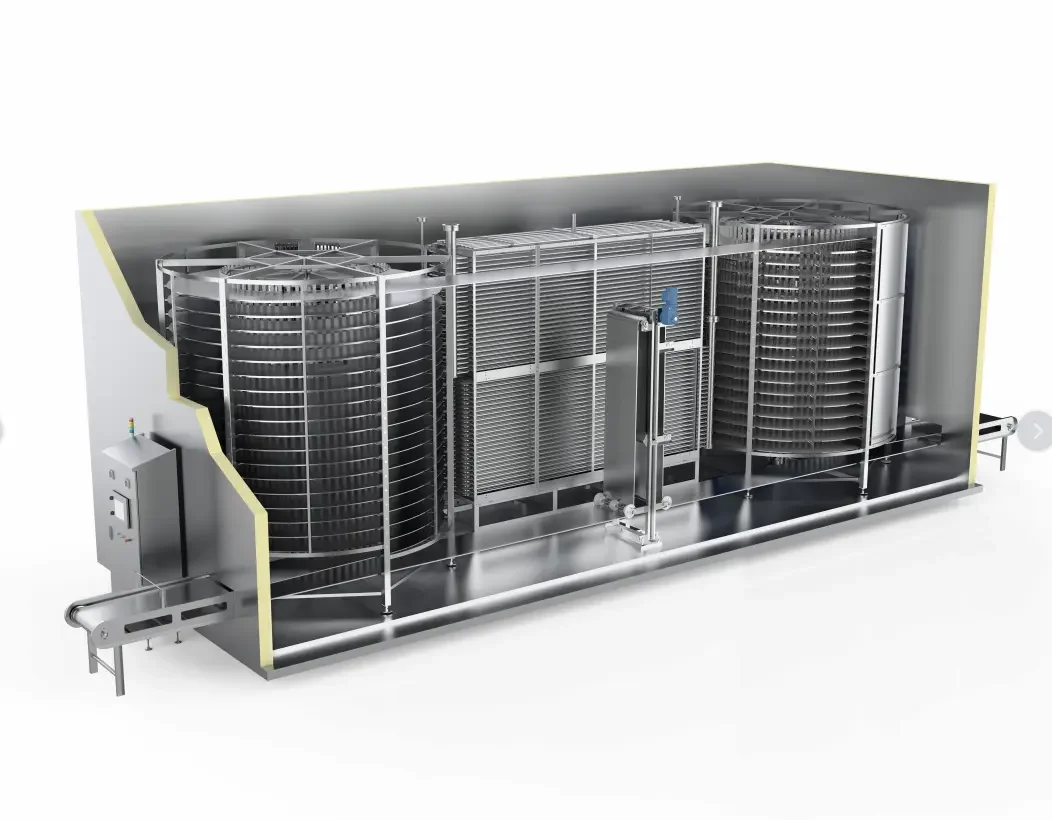

Spiral Freezer

-

The low-tension spiral freezer with double drums produced by Square Technology is applicable to individual quick frozen of granulated and small-piece food, and large-sized frozen food, such as prepared meals, whole chicken, and whole fish.

Double drum spiral freezer positions infeed and outfeed at low making it convenient for operation and better matching the production lines of customers.

Custom-built to meet specific customer requirements

Capacity ranges from 200kg to 10000kg/hr

The structure's open design ensures total accessibility for easy cleaning and maintenance.

It includes a computerized control system with pre-programmed cleaning modes and an optional automatic CIP to reduce cleaning effort and time.

The enclosure is designed for optimal insulation and waterproofing, with choices between fully welded or groove-tongue caulking.

-

Synchronized Triple Drive

SUS304 fully welded structure, heavy load, easy for maintenance.

Variable belt speed.

SUS304 food grade spring wire, high strength, 8-10 years’ service life.

Open structure, easy for cleaning, width suitable: 400~1372mm.

Optional edge guard board to prevent products dropping.

The design was simulated with European professional heat exchanger software.

All tubes are expanded hydraulically rather than mechanically. More uniform expansion and tighter fit between tube and fins. Improved heat exchanging performance.

Variable fin pitch used to delay the frost formation on the fins surface. Longer frosting interval.

Easy access and cleaning

Tube material: Stainless steel, Aluminum

Fin material: AluminumContinuous PIR panel fabrication line from German Hennecke. 50mm to 250mm thick. Limited combustibility.Fully welded stainless steel enclosure available as option.

The cold and high velocity air flow is guided with the air baffles evenly through the product area.

Minimum food dehydration, best heat transfer.

Air shrouds provided to minimize cold loss at the opening of infeed and outfeed.

Spacious access inside freezer for maintenance and cleaning personnel.

-

Structure1 Double spiral freezer Drum diameter 1620 5800mm

Layers 6-40

Insulated enclosure PIR/PU, SS skin at both sides

Mesh belt width 520-1220mm

Infeed length 500mm

Outfeed length 500mm

Control panel PlC touch screen, SS panel

Refrigerant Freon, Ammonia, CO2

Evaporator Al/SS tube, aluminum fin, variable fin pitch

Defrost Water/hot gas/ADF optional

Freezing\cooling time Stepless variable frequency adjustable

Cleaning Manual/Belt Washer/CIP

Structure2 Single drum spiral freezer

Drum diameter 1620-5800mm

Layers 6-40

Insulated enclosure PIR/PU, double sides stainless steel panel

Mesh belt width 520~1372mm

Infeed length 500mm

Outfeed length 500mm

Control panel PLC touch screen, SS panel

Refrigerant Freon, Ammonia, CO₂

Evaporator Al/SS tube, aluminum fin, variable fin pitch

Defrost Water/hot gas/ADF optional

Freezing\cooling time Stepless variable frequency adjustable

Cleaning Manual/Belt Washer/CIP

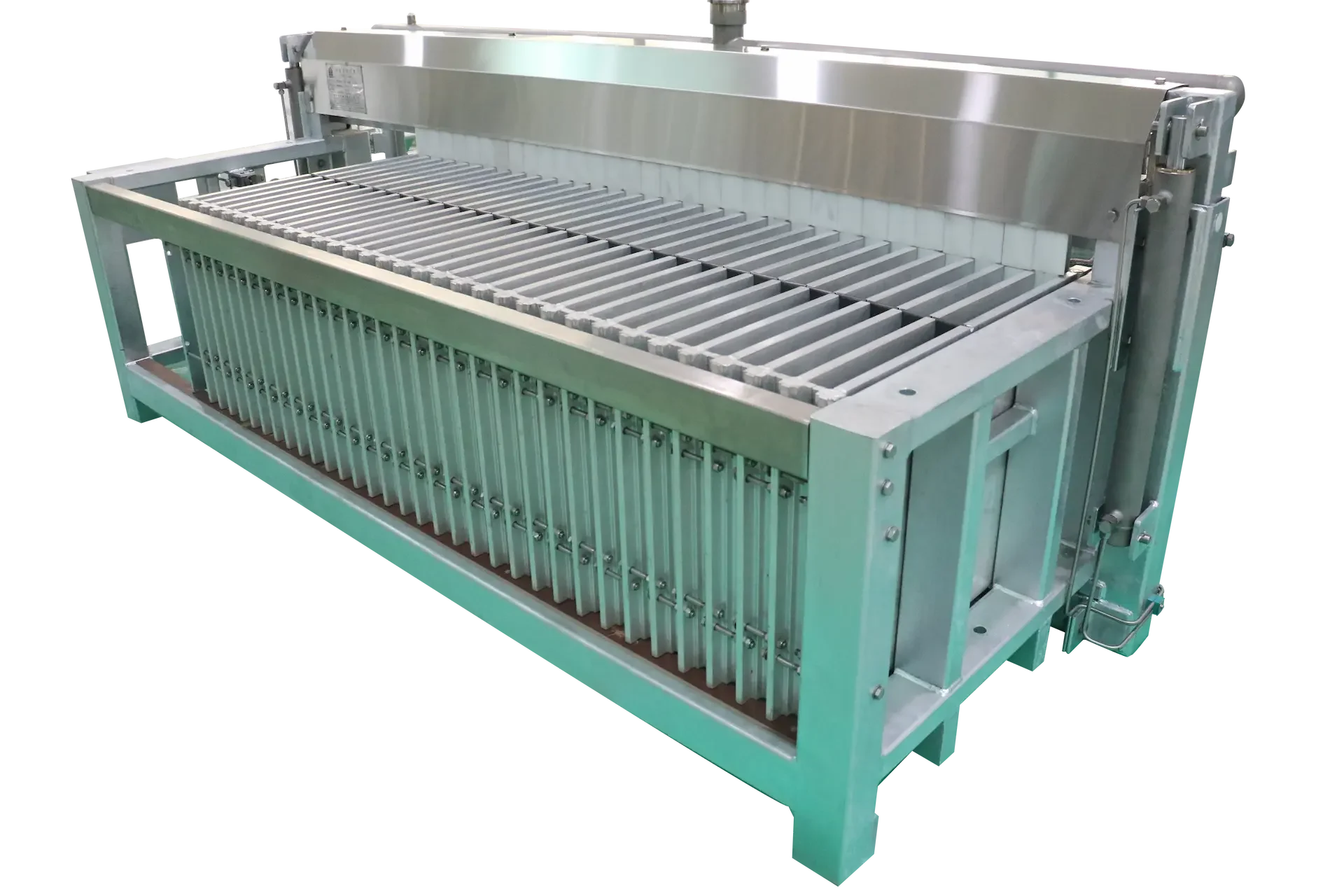

Plate Freezer

-

Plate freezer is suitable for frozen blocks, such as fish, shrimp, surimi, meat, pet food, juice, etc. Our Plate freezers are commonly used for freezing brick-shaped products in mold or boxes. In plate freezers, refrigerant is allowed to circulate inside thin channels within the plates.

The packaged products are firmly pressed between the plates. High rates of heat transfer can be obtained between the packaged product and the evaporating plates.

-

Unique one-piece insulated enclosure with better insulation and strength.

Full stainless steel structure with good appearance, easy to clean.

Aluminum-alloy evaporative plate with better freezing capacity.

Separate liquid supply and suction for each plate, even supply with high efficiency and better freezing performance.

Mass production, freeze in blocks.

-

Freezing MethodDouble-sided contact freezing

Plate Size (Single Plate)2000 × 1000 mm or 2000 × 1200 mm

Effective Freezing Area10–20 m² (depending on plate count)

Plate Thickness20–30 mm (aluminum alloy)

Cooling Capacity50–300 kW (depending on configuration)

Operating Temperature–35°C to –45°C

Compressor Power15–60 kW

Plate Movement SystemHydraulic lift or pressure mechanism

External Dimensions (L×W×H)3000×2000×3000 mm ~ 5000×2500×3200 mm

MaterialStainless steel shell with polyurethane insulation

Cleaning DesignPlates open for easy cleaning

RefrigerantsNH₃, R404A, R507, or CO₂

Control SystemPLC + temperature sensors, optional touchscreen interface

Fully Automatic Forming Machine 260

-

The AMF260-II is a fully automatic forming machine designed for small to medium production volumes, with a capacity of 100–300 kg/hour. It inherits the core technology of the AMF600 series, making it ideal for laboratory trials in large factories and for continuous production in smaller facilities. The machine ensures that experimental data aligns with large-scale production, providing accurate process parameters for scaling up. It is suitable for forming various meat products with high consistency, quality, and efficiency.

-

Touchscreen & PLC Control: User-friendly interface for easy operation and precise monitoring.

High-Precision Hydraulic System: Ensures accurate filling and consistent weight control for every product.

Spiral Feeding System: Gap-controlled feeding prevents damage to meat fibers, maintaining product texture and quality.

Template Control System: High-speed hydraulic drive for consistent product weight, easy template replacement, and compatibility with various template designs.

Hygienic & Safe Design: Constructed mainly of stainless steel and selected non-metallic materials, compliant with HACCP standards.

-

Model: AMF260-II

Belt Width: 260 mm

Power: 5.56 kW

Production Rate: 100–300 kg/h

Stroke Frequency: 30–60 strokes/min

Product Thickness: 6–25 mm

Dimensions (L×W×H): 2513 × 709 × 1950 mm

Rail System

-

The Rail System is a fixed-path track infrastructure designed to guide and support automated vehicles or carts (such as RGVs) for material transfer within production facilities. It ensures precision movement, stability, and efficiency in environments requiring strict hygiene and controlled conditions, such as wet meat processing, cold storage, and freeze-drying plants.

Including: 1#RGV/2#RGV ground rails, trolley rail in the blast freezer, trolley rail in the preprocessing room and post-processing room

-

High-Precision Alignment

Maintains consistent positioning for docking stations, reducing cycle errors.

Heavy-Duty Construction

Stainless steel or coated steel rails for durability and hygiene compliance.

Adaptable Layout

Supports straight, curve, and switch rail configurations to optimize floor space.

Cold Environment Ready

Special design for sub-zero conditions, preventing track freezing or deformation.

Integrated Power & Communication

Conductor rails or cable chains for continuous power supply.

Data transmission for vehicle control (wired or wireless).

-

Load Capacity: Supports carts or RGVs up to 1,500 kg

Rail Material: Stainless steel or galvanized steel

Track Type: Floor-mounted or embedded

Guidance Accuracy: ±2 mm

Environment: Capable of operating at -40 °C in freezing zones

RGV

-

The Rail Guided Vehicle (RGV) is an automated material transfer solution designed to enhance efficiency and safety in food production, freeze-dry facilities, and cold storage environments. Operating on a fixed rail track, the RGV ensures precise, reliable, and high-speed transportation of trays, trolleys, or material carts between different processing zones.

-

Automated Material Handling

Transports loaded or empty trolleys and tray carts between loading stations, freeze-dry chambers, and packaging areas.

Integrates seamlessly with tray loading/unloading machines and conveyor systems.

High Precision & Speed

Controlled by PLC-based automation for accurate positioning.

Capable of handling multiple stop points along the rail for flexible operations.

Cold Environment Ready

Designed for sub-zero working conditions (up to -20°C).

Corrosion-resistant materials suitable for hygienic environments.

Safety & Reliability

Equipped with anti-collision sensors, emergency stop, and obstacle detection.

Smooth acceleration and braking to protect products during transit.

Smart Integration

Compatible with Industry 4.0 systems, offering real-time monitoring and remote control.

Optional RFID tracking for cart identification and process traceability.

-

Load Capacity: 500–1,500 kg per cart

Speed: 30–60 m/min (adjustable)

Drive Type: Electric motor with rail guidance

Power Supply: Conductor rail or battery-powered options

Operating Temperature: -20°C to +40°C

Trolley

-

The Stainless Steel Trolley is an essential material handling moving solution for high-volume food processing and freeze-dry operations. Designed for hygiene, strength, and maneuverability, it facilitates the safe and efficient transfer of products between processing stages.

-

Durable Construction

Manufactured from SS304 or SS316L stainless steel for corrosion resistance and compliance with food safety standards.

Heavy-duty frame engineered to handle high weight loads.

Ergonomic & User-Friendly

Low loading height for easy product transfer.

Handles positioned for optimal operator comfort.

Mobility

Fitted with 4 swivel casters (2 with brakes) for smooth, controlled movement.

Silent, heavy-duty wheels suitable for cold storage and sub-zero environments.

Hygienic Design

Open structure for easy cleaning.

Rounded corners and sloped surfaces prevent residue buildup.

-

Model:WLC-64

Capacity:64 trays

Size(mm):1396*1420*1720

Weight(kg):210

Material:SS304

Capacity: 200–1000 kg (customizable)

Wheel Type: High-strength polyurethane or stainless steel

Operating Temperature: Suitable for cold rooms and blast freezers

Tray Washer

-

The Tray Washer Machine is an automated cleaning solution designed to ensure hygienic washing, sanitization, and drying of trays used in food, pharmaceutical, and freeze-drying operations. It provides consistent cleaning performance, reduces manual labor, and ensures compliance with stringent food safety standards.

-

High-Pressure Multi-Stage Cleaning

Pre-wash, main wash, rinse, and sanitization stages.

Removes meat residues, oils, and biofilm effectively.

Hygienic Design

Constructed from stainless steel (SS304/316L).

Sloped surfaces and open frame for easy drainage and cleaning.

Automation & Efficiency

Compatible with conveyor-fed tray loading and unloading systems.

Optional robotic tray handling for fully automated lines.

Temperature & Chemical Control

Heated wash water up to 80°C for enhanced sanitization.

Automatic detergent dosing and pH monitoring.

Drying System (Optional)

Integrated hot-air or air-knife drying for rapid moisture removal.

User-Friendly Interface

PLC & HMI control panel for recipe-based cleaning programs.

Data logging for compliance and audit reporting.

-

Tray Washer Machine

The Tray Washer Machine is an automated cleaning solution designed to ensure hygienic washing, sanitization, and drying of trays used in food, pharmaceutical, and freeze-drying operations. It provides consistent cleaning performance, reduces manual labor, and ensures compliance with stringent food safety standards.

Model:WPJ01-03

Size(mm):9585×1700×2000.

Brush configuration: two sets and four brushes.

one set in pre-cleaning sections, and the other set in cleaning sections.

Chain specifications: SS12A-1 straight conveyor chain is used.

Water consumption: 1.3m³ of water is added

Tray moving: It adopts servo motor acceleration and reducer transmission.

Capacity:240-600 trays/hour

Weight(kg):3500

Material:AISI304

Powe: 480V/60Hz/65kw

Throughput: 200 – 1,200 trays per hour (customizable).

Tray Size Range: Standard and custom formats (e.g., 400×600 mm, 600×800 mm).

Water Recycling: Integrated filtration and optional heat recovery.

Compliance: Meets FDA, USDA, CE standards.

Tray Rack

-

The Stainless Steel Tray Rack is a robust and hygienic material handling solution, designed for use in freeze-drying, meat processing, and food production environments. Built for durability and compliance with strict sanitation standards, it ensures efficient tray organization, easy mobility, and long service life.

-

Heavy-Duty Construction

Made from high-grade stainless steel (SS304/316L) for corrosion resistance and hygienic use.

Fully welded frame for strength and stability under heavy loads.

Multi-Layer Design

Optimized for maximum tray capacity (typically 64 layers per side, 2 sides = 128 trays per rack).

Compatible with industry-standard freeze-dry trays.

Easy Mobility

Equipped with high-quality swivel casters for smooth movement across processing areas.

Locking wheels ensure stability during loading and unloading.

Ergonomic & Modular

Designed for quick tray loading/unloading in automated or manual workflows.

Compact footprint for efficient floor space utilization.

-

Model:TPJ-128

Capacity:128 trays

Size(mm):1060*740*1980

Weight(kg):60

Material:SS304

Capacity: Up to 128 trays per rack (customizable)

Dimensions: Standard or custom sizes available

Mobility: 4 industrial-grade caster wheels with locks

Temperature Range: Suitable for cold rooms and sub-zero environments

Tray

-

The Tray designed to load product onto trays with precision, speed, and hygiene. It is an essential component in freeze-drying operations and high-capacity food production facilities.

-

Flat or slightly recessed base with perforated or solid surface, depending on the product form (liquid, paste, solids).

Optional Teflon or electropolished finish for easy product release and cleaning.

Hygienic & Safe Design: Constructed mainly of stainless steel and selected non-metallic materials, compliant with HACCP standards.

-

Size(mm):671×604×37

Thinkness:1.5mm

Material:LF2

Weight:2.6kg

Tray load Weight:Max.8.5 kg

All surfaces are anodized, with an oxide layer

thickness of 10μm