Makes Business Easier

Corona, LA

From the installation of the freeze-drying chamber to fully commissioning, the entire process was completed in just six months.

7 Phases Verification.

This is a $25 million fully integrated project that encompasses the entire production chain — from frozen storage and temperature-controlled buffering warehouses to raw meat pre-processing, refrigeration and freeze-drying systems, automated packaging, and finished goods warehousing.

The production line is supported by a comprehensive range of automated equipment, significantly reducing labor requirements while greatly improving efficiency, throughput, and process consistency.

With optimized workflow design and intelligent automation, the facility achieves an annual production capacity of 2,000 tons of premium freeze-dried products, ensuring high-quality output and sustainable industrial scalability.

Tray Layer to Tray Loader

This system automatically spreads the material into trays, layer it uniformly, stacks the trays, and then loads them onto the material rack.

Tray Unloader to Tray Washer

This system automatically unloads the trays and transfers them via a robotic arm to the tray washer for cleaning.

American Fork, UT

This production line begins on the third floor, where the mixing system blends up to four different ingredients. After mixing, the product passes through a vibrating drum for precise proportioning before being transferred to the second-floor multihead weigher for accurate dosing.

The weighed product is then discharged into the first-floor packaging machine for bag forming, filling, and sealing. Each finished bag proceeds through a checkweigher and an X-ray inspection system to ensure weight accuracy and product safety.

After inspection, an automated robotic spider arm picks and places the bags into cartons. The filled cartons are then conveyed to the case sealer for automatic sealing, and finally transported for palletizing, completing a fully integrated and highly efficient packaging workflow.

Oak Creek, WI

This is a complete large-bucket material cartoning process — from carton forming and bag inserting, to filling, bag sealing and pressing, and finally carton sealing — achieving a fully automated and continuous packaging workflow.

This is another production line in Oak Creek, WI. This process begins with bulk materials being discharged into the Z-type bucket elevator, which transfers the product to the second-floor platform where the multihead weigher performs accurate weighing and dosing. The measured product is then released into the packaging machine for bag forming, filling, and sealing.

After packaging, the finished bags are conveyed to the packing area for cartooning. An automatic case erector continuously supplies formed cartons to the operators for efficient case loading. Once filled, the cartons are transferred onto the conveyor for automatic case sealing, completing the streamlined and automated packaging workflow.

There are three Tray Washer in Oak Creek, WI. This is the most popular machine for the food industry. And this is how our machine works in real operation process and that efficiency.

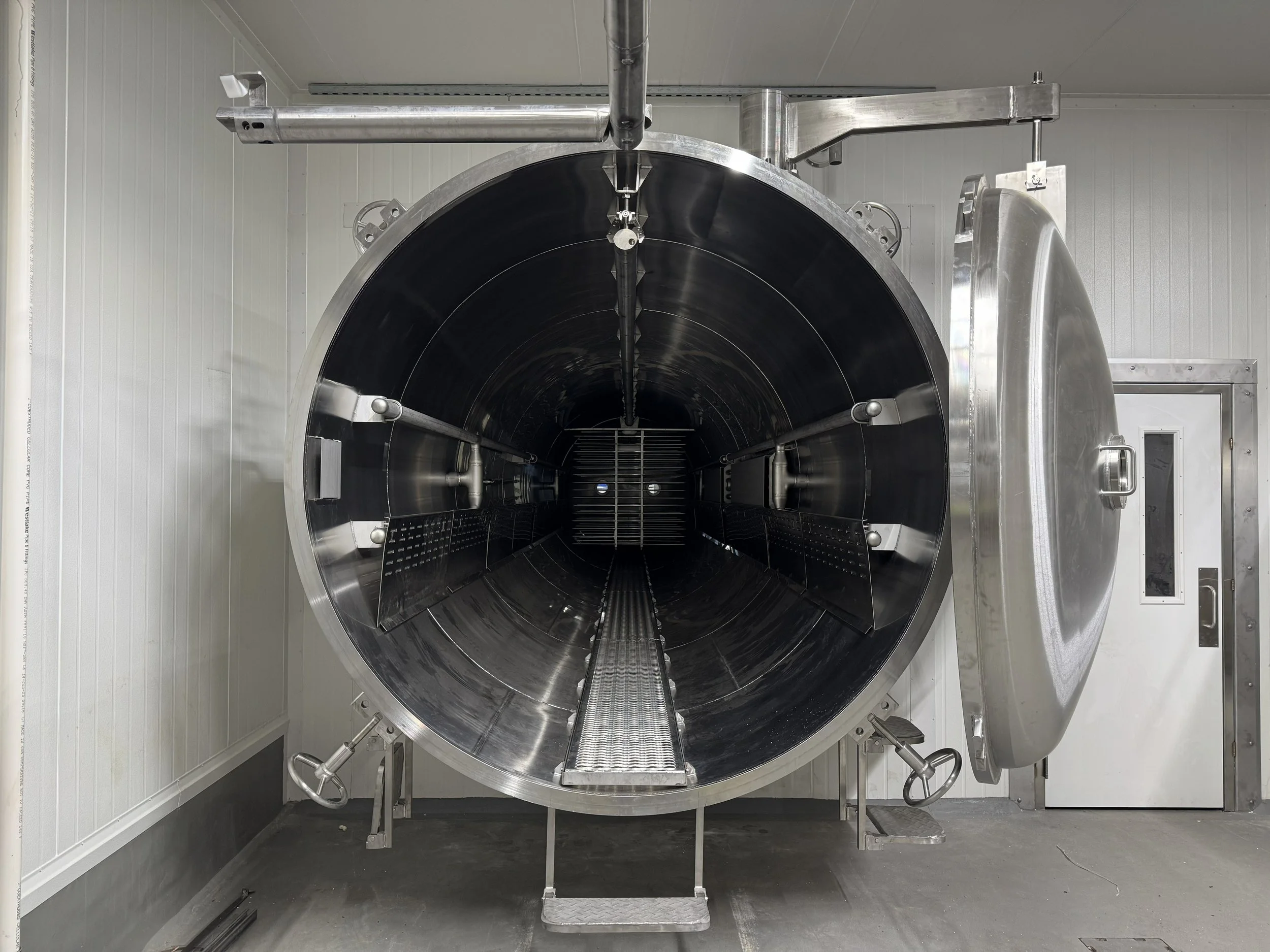

SSP Sterilization Chamber

The SSP Sterilization Chamber is an automated high-efficiency sterilization system designed for bulk materials, semi-finished products, or packaged goods. By utilizing controlled cycles of superheated steam, high-temperature air, or other validated sterilization media, the SSP chamber ensures rapid and uniform microbial inactivation while preserving product quality and integrity.

-

High Sterilization Efficiency – Achieves validated microbial reduction levels suitable for food, nutraceuticals, and pharmaceutical pre-processing.

Uniform Temperature Distribution – Multi-zone heating and circulating airflow ensure consistent sterilization across all trays and material layers.

Fully Automated Operation – Automatic door control, cycle programming, data logging, and safety interlocks.

Hygienic Stainless-Steel Construction – 304/316L stainless steel frame for GMP-compliant environments.

Flexible Loading System – Compatible with tray carts, containers, or bulk loading mechanisms.

Energy-Efficient Design – Optimized heat recovery and insulation reduce operating costs.

Real-Time Monitoring – PLC + HMI system with temperature, pressure, and humidity tracking.

-

Temperature Range: 75°C – 150°C (or customized based on process)

Sterilization Cycle: 20–90 min depending on product type

Capacity: 500–3000 kg per batch (customizable)

Control Accuracy: ±0.5°C temperature / ±1% humidity

Microbial Reduction: Up to 5–7 log depending on validation requirements

Chamber Size: Configurable for single-door or pass-through (double-door) layouts

-

Pet food ingredients

Freeze-dried material pre-treatment

Meat and seafood pasteurization

Grain, powders, and dehydrated vegetable sterilization

Pharmaceutical pre-sterilization processes

Nutraceuticals and botanical extracts

Packaging material sterilization (if required)

-

Enhanced Product Safety – Eliminates pathogens such as Salmonella, E. coli, Listeria, molds, and spores.

Improved Production Efficiency – Integrates seamlessly with upstream and downstream automated lines.

Quality Retention – Maintains flavor, color, and nutrient profile better than traditional high-temperature sterilization.

Regulatory Compliance – Supports FDA, CFIA, EU, and GMP validation standards.

Reduced Labor – Automated loading/unloading options reduce manual handling and improve consistency.

Scalable Design – Suitable for factories from small batch production to large-scale industrial processing.