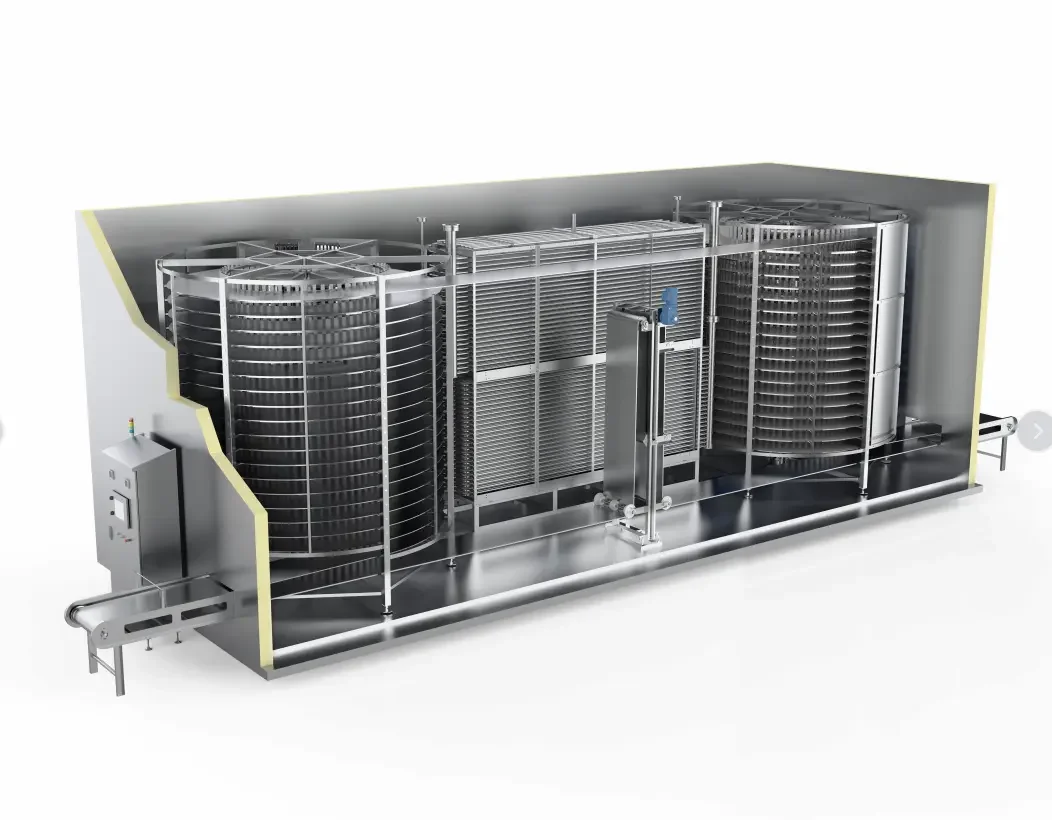

Spiral Freezer

The The low-tension spiral freezer with double drums produced by Square Technology is applicable to individual quick frozen of granulated and small-piece food, and large-sized frozen food, such as prepared meals, whole chicken, and whole fish.

Double drum spiral freezer positions infeed and outfeed at low making it convenient for operation and better matching the production lines of customers.

Custom-built to meet specific customer requirements

Capacity ranges from 200kg to 10000kg/hr

The structure's open design ensures total accessibility for easy cleaning and maintenance.

It includes a computerized control system with pre-programmed cleaning modes and an optional automatic CIP to reduce cleaning effort and time.

The enclosure is designed for optimal insulation and waterproofing, with choices between fully welded or groove-tongue caulking.

Key Features

Large Sprocket / chain Drive

Synchronized Triple Drive

SUS304 fully welded structure, heavy load, easy for maintenance.

Variable belt speed.

Stainless Steel Mesh Belt

SUS304 food grade spring wire, high strength, 8-10 years’ service life.

Open structure, easy for cleaning, width suitable: 400~1372mm.

Optional edge guard board to prevent products dropping.

Efficient evaporator

The design was simulated with European professional heat exchanger software.

All tubes are expanded hydraulically rather than mechanically. More uniform expansion and tighter fit between tube and fins. Improved heat exchanging performance.

Variable fin pitch used to delay the frost formation on the fins surface. Longer frosting interval.

Easy access and cleaning

Tube material: Stainless steel, Aluminum

Fin material: Aluminum

Insulated enclosure

Continuous PIR panel fabrication line from German Hennecke. 50mm to 250mm thick. Limited combustibility.Fully welded stainless steel enclosure available as option.

Fully welded floor

Modular stainless steel fully welded floor, leak proof.

Sloped floor, fast drainage through four drains at the corners. Easy Access.

Air Flow Design

The cold and high velocity air flow is guided with the air baffles evenly through the product area.

Minimum food dehydration, best heat transfer.

Air shrouds provided to minimize cold loss at the opening of infeed and outfeed.

Spacious access inside freezer for maintenance and cleaning personnel

Intelligent control system

PLC touch screen, friendly interface, easy operation.

Real-time display of equipment running status, temperature of each area, fault alarm.

Preset freezing programs tailored for different products.

Optional remote troubleshooting module.

Air defrost system

The ADF blows pulses of pressurized air of high velocity repeatedly over the evaporator fins while the products continue to run in the freezer.

The freezer inside temperature is more stable because of less frost on the fin.

Thanks to longer runtime, the production output is increased.

CIP(Cleaning-in-Place)

The system cleans and disinfects the interior of the freezer completely to meet the sanitary requirements of food safety production.

Our system design is programmed with tailored CIP recipes to suit various product and needs.

Performance Metrics

Structure1 Double spiral freezer Drum diameter 1620 5800mm

Layers 6-40

Insulated enclosure PIR/PU, SS skin at both sides

Mesh belt width 520-1220mm

Infeed length 500mm

Outfeed length 500mm

Control panel PlC touch screen, SS panel

Refrigerant Freon, Ammonia, CO2

Evaporator Al/SS tube, aluminum fin, variable fin pitch

Defrost Water/hot gas/ADF optional

Freezing\cooling time Stepless variable frequency adjustable

Cleaning Manual/Belt Washer/CIP

Structure2 Single drum spiral freezer

Drum diameter 1620-5800mm

Layers 6-40

Insulated enclosure PIR/PU, double sides stainless steel panel

Mesh belt width 520~1372mm

Infeed length 500mm

Outfeed length 500mm

Control panel PLC touch screen, SS panel

Refrigerant Freon, Ammonia, CO₂

Evaporator Al/SS tube, aluminum fin, variable fin pitch

Defrost Water/hot gas/ADF optional

Freezing\cooling time Stepless variable frequency adjustable

Cleaning Manual/Belt Washer/CIP

Applications

Bakery Products: raw bread dough, pizza dough, croissant, baked bread, buns. It can also cool the baked bread to ambient temperature for packing later.

Seafoods: including whole fish, fish fillet, shrimps, shellfishes, octopus, etc. Ready-to-eat meals and frozen food lines

Ready Meals: the packed meals, flight meals and microwave meals can also be frozen or cooled by the spiral freezer. The freezing time can be less than 1.5 hours from cooked temperature to -18C.

Poultry products(raw): freezing raw chicken parts efficiently, including chicken wings, breasts, thighs, fillets, etc. The capacity can range from 500kg to 5 tons/hour. Our major poultry customers include Tyson Foods, CP Foods, Cargill, Sunner, etc.

Poultry products(cooked): freezing the fried chicken nuggets for major fast food chains, including KFC, Mcdonald’s, Pizza Hut, Burger King, etc. The most common capacity is between 500kg to 4 tons/hour. The freezer is equipped with a CIP system to clean the freezer automatically after each workshop.

Ice Cream: ice cream hardening. It can quickly harden the ice cream in boxes from -4℃ to -18℃. The major ice cream brands, are Unilever, Walls, Baxi, Haagen Dazs, etc. It is more efficient and energy-saving than the traditional static blast freezer.

Chinese Pastry products: freezing Chinese pastries, including steamed buns, buns, dumplings, spring rolls, Indian parathas, etc. Our major customers include Kawan Foods, Sanquan Foods, Anjoy Foods, Sinian Foods, etc. The production capacity ranges from 300kg to 3000kg/hr.

Benefits

Compact design with high throughput

Uniform and fast freezing

Energy efficiency

Customizable belt width, tier height, and freezing time

Compatible with various packaging types (tray, bag, loose)