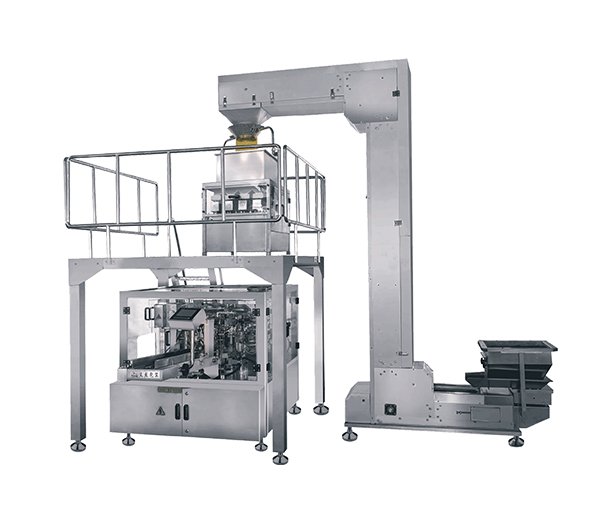

Block-Form Bagging Machine

The Block-Form Bagging Machine is designed to handle single-material or multi-material mixed packaging, ensuring complete product variety and accurate measurement. It is ideal for a wide range of food, frozen, pet, spice, pharmaceutical, and non-food applications, providing a fully customized automated packaging solution for clients.

Supporting Equipment: Combination scales, platforms, Z-type elevators.

Bag Types: Flat bags, flat zipper bags, stand-up pouches, corner-fold bags, and more.

Packaging Capacity (bags/min):

Machine Type : Block-Form Bagging Machine

Bag Types : Flat bags, zipper bags, stand-up pouches, corner-fold bags

Packaging Capacity : Single lane: 20–50 bags/min; Double lane: 40–90 bags/min

Materials: Stainless steel (machine body), 403/316L stainless steel (contact parts)

Control System : PLC with touchscreen interface, MES system compatible

Sealing Quality : Flat, smooth, no wrinkles; precise bag positioning

Key Features

High-Quality Construction:

Machine body made of stainless steel; contact parts made of 403/316L stainless steel or other sanitary materials.

Corrosion-resistant, durable, and hygienic.

User-Friendly Operation:

Easy installation and simple operation.

PLC touchscreen interface, compatible with user MES systems.

Precise Material Control:

Controlled by the weighing system to release material accurately, minimizing waste.

Empty bag detection prevents sealing of unfilled bags, saving packaging materials.

High-Quality Packaging:

Specially designed sealing and shaping station ensures smooth, wrinkle-free seals.

Clear bag patterns, high seal quality, and extremely low package failure rate, reducing material costs.

Easy Maintenance:

Mainly mechanical transmission with lubricated bearings, reducing maintenance needs.

Quick and convenient access for inspection and repair.

Performance Metrics

Packaging Speed (bags/min)Single Line: 20–50

Double Line: 40–90Pouch TypesFlat Bag, Zipper Bag, Stand-up Pouch, Gusseted Bag

Supporting EquipmentMultihead Weigher, Platform, Z-type Elevator

Structure MaterialSUS304 / SUS316L Stainless Steel

Applications

1. Nuts & Roasted Seeds

Sunflower seeds, pistachios, walnuts, cashews, almonds, pecans, pine nuts, chestnuts, etc.

2. Snack Foods

Candies, jellies, cheese sticks, hawthorn sticks and balls, gummies, potato chips, fries, dried fruits, dried berries, coffee beans, puffed foods, etc.

3. Frozen Foods

Frozen shrimp, beef tripe, corn kernels, rice cakes, chicken legs, hotpot meatballs, frozen vegetables, and other ready-to-cook products.

4. Pet Foods & Supplies

Dog food, cat food, hamster and bird feed, pet treats, chicken breast strips, mixed dry food, baked and freeze-dried meals, mealworms, and cat litter.

5. Spices & Seasonings

Star anise, peppercorns, bay leaves, rock sugar, and other granular or irregular condiments.

6. Health & Daily Products

Herbal medicine slices, health supplements, laundry pods, disposable toothbrushes, shower caps, and hotel amenities.

Benefits

Multi-industry flexibility: One machine supports a variety of materials, pouch types, and product forms.

High efficiency: Dual-line operation doubles productivity with precise weighing control.

Reduced material and bag waste: Smart filling and sealing logic minimize resource consumption.

Hygienic & long-lasting: Built to meet international food-grade standards with durable stainless-steel construction.

Easy integration: Can be seamlessly combined with upstream and downstream processing systems for a complete automated packaging line.

Low maintenance & high reliability: Simple mechanical structure with reduced wear parts ensures long-term stable performance.